Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

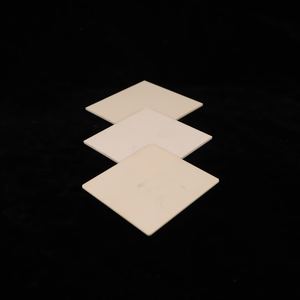

Overview of Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block

Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block)

Specification of Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block

Alumina rubber plates with ceramic inserts are essential for tough mining processing jobs. These plates protect key equipment from severe wear. Mining operations constantly handle abrasive materials. This causes rapid damage to surfaces. Standard steel liners wear out too quickly. Rubber alone isn’t hard enough. Ceramic offers extreme hardness. Alumina ceramic is one of the hardest materials available. It resists abrasion exceptionally well. Rubber provides crucial impact absorption. Combining these materials creates a superior solution. The ceramic inserts are embedded deep within a tough rubber matrix. This design locks the ceramic securely in place.

The rubber absorbs the shock from heavy impacts. Rocks and ore hitting the surface don’t shatter the ceramic. The ceramic surface itself provides the wear resistance. Abrasive materials slide over it without causing significant damage. The rubber backing flexes slightly under load. This flexibility helps the plate conform to surfaces. Installation is straightforward. The plates can be bolted or bonded onto equipment. Common applications include chutes, hoppers, bins, and transfer points. These areas see constant material flow and impact.

These plates last much longer than standard steel liners. This reduces downtime for replacements. Maintenance costs go down significantly. Workers spend less time changing out worn liners. The rubber base also dampens noise. Mining environments are very loud. Reducing noise improves safety for workers. The plates are also lighter than equivalent steel liners. Handling them is easier and safer. Equipment structures experience less stress. The ceramic surface remains smooth during use. Material flow stays consistent. Blockages and build-up are minimized. This ensures efficient operation. Choosing the right thickness and ceramic block size matters. It depends on the specific impact and abrasion levels. These plates are a reliable defense against wear. They keep mining equipment running longer and smoother.

(Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block)

Applications of Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block

Mining processing equipment faces extreme wear daily. Abrasive materials constantly scrape and tear at vital surfaces. This damage causes expensive downtime and replacement costs. Standard rubber linings help but often fail too quickly under such punishment. Ceramic-reinforced rubber plates offer a much tougher solution.

These plates combine a strong rubber base with embedded alumina ceramic blocks. Alumina ceramic is extremely hard. It resists abrasion far better than steel alone. The ceramic inserts take the direct impact from rocks and ore. They shield the rubber underneath. The flexible rubber backing absorbs shock. It prevents cracking or shattering of the ceramic. This dual-action protection significantly extends component life.

The plates are designed for straightforward installation. They use bolts or adhesive systems. This allows quick fixing onto chutes, hoppers, bunkers, or truck beds. Workers can replace worn sections easily. There’s no need to remove entire linings. This saves valuable maintenance time.

The ceramic blocks are densely packed within the rubber. This creates a nearly smooth surface. Materials slide freely over it. There’s minimal sticking or buildup. This keeps material flow consistent. It prevents blockages that slow down operations.

These plates are built for the toughest mining jobs. They excel in primary crusher feed areas. They protect transfer points where rocks drop. They line screening decks and classifier tanks. They guard slurry pipelines against scouring wear. Anywhere heavy, sharp materials move, these plates hold up. They drastically cut maintenance frequency and cost. They keep critical processing equipment running longer. This boosts overall plant productivity.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block

What makes these plates last longer than regular rubber?

The ceramic blocks inside the rubber are super hard. They take the direct hits from rocks and slurry. The tough rubber holds the blocks firmly. This combination stops wear incredibly well. The ceramics shield the rubber underneath. This protection is key.

Why use ceramic blocks instead of solid steel?

Ceramic is much harder than steel. It resists abrasion far better. It doesn’t deform under impact like steel sometimes can. The ceramic surface stays smooth. This helps material flow better. It reduces friction buildup. Steel wears down faster in gritty conditions.

Is installing these plates difficult?

No, installation is straightforward. The plates have pre-drilled holes. You bolt them directly onto your equipment structure. The process is similar to fitting standard rubber liners. You need standard tools. It doesn’t require special skills or extra time. You get them working fast.

Do they need special maintenance?

Very little extra maintenance is needed. Check bolt tightness regularly like any liner. Look for any cracked ceramic blocks during routine checks. Replacing a single damaged plate is easy. The overall system is simple. It avoids complex upkeep demands.

Do they really save money?

Yes, they significantly cut costs long-term. Their extreme wear resistance means replacements happen much less often. Your equipment experiences less downtime for liner changes. Production keeps running longer. The initial cost is higher than basic rubber. The extended service life provides a much better return. You spend less over time.

(Mining Processing Industry Alumina Rubber Plate With Ceramic Inserts / Block)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramic Liner Plate Al2O3 Ceramic Piece

99Al2O3 Industrial Alumina Ceramic Plate

99% High Hardness Al2O3 Ceramic Hexagon Alumina Plate Zirconia Material Body Protective Refractory Applications Welding Cutting

Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services

Wear Resistant Alumina Ceramic Plates with Steel Back