Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

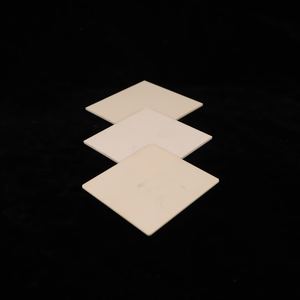

Overview of OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate

OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate)

Specification of OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate

This alumina ceramic home heating plate takes care of high warm dependably. It’s constructed hard for demanding commercial work. The material is alumina ceramic. This things endures extreme temperatures conveniently. It will not split or warp under intense warmth cycles. That makes it ideal for continuous use.

You get uniform warm spread throughout the entire disc surface. Locations are avoided. This guarantees consistent performance every time. The warm transfers successfully to whatever remains on top. Think lab equipment parts, semiconductor devices, or specialized machinery elements requiring specific warm.

We provide numerous shapes and sizes. Round discs are common. Square or personalized forms function also. Inform us your needed measurements. We can make it fit your details devices. Wattage choices are flexible. Low electrical power provides mild heat. High power level supplies intense warmth fast. Voltage choices include standard a/c or DC choices. We match your power supply.

The heating element is embedded safely inside the ceramic. This shields the aspect from damages. It also stops electrical threats. Surface temperature levels can get to really high levels safely. The ceramic itself stays secure and non-reactive. It does not launch fumes or contaminate your process.

Modification is our toughness. Need specific placing openings? We pierce them. Call for unusual lead cords? We connect them. Special surface coatings? We provide them. This plate integrates smoothly right into your existing arrangement. It’s made for OEM and ODM projects. We construct specifically what your product calls for. Efficiency is reliable over the long term.

(OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate)

Applications of OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate

OEM ODM thermal heating system discs utilize high temperature alumina ceramic. These plates heat up quick and handle severe heat well. They spread out heat equally throughout their surface. This makes them reputable for lots of industrial work. Manufacturing facilities require constant warmth for manufacturing. These ceramic plates deliver that.

Semiconductor firms use them for bonding and treating electronic devices. They heat up motherboard exactly. Plastic welding equipment relies on them as well. They thaw and seal plastic packages properly. Food processing lines make use of these heating units for sealing bags and drying food. They maintain the warm consistent for secure food handling.

Medical tools need tidy, trustworthy warm. These alumina plates sterilize instruments. They heat samples in diagnostic equipments. Laboratories use them inside screening stoves and heaters. They heat up materials for experiments precisely. Aerospace firms need parts that last. These heating systems work inside sensing units and other critical equipment. They deal with the hard problems.

Personalization is vital for OEM ODM companions. We make these heating systems in lots of shapes and sizes. We fit them into your specific equipment layout. Voltage and power level match your power needs. Installing openings and ports are positioned just right. This saves you engineering time. You get a heater prepared for your assembly line.

Alumina ceramic is difficult. It stands up to chemicals and will not wear away. It lasts much longer than steel heating units. The warmth remains also, no locations. This protects your items during heating. Makers run much longer without heater failings. You obtain reduced downtime and upkeep costs.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate

What’s the highest temperature this heating plate handles?

It reaches 1600°C maximum. Pure alumina ceramic handles extreme heat well. This suits demanding industrial processes. Check your specific model’s exact rating.

What makes alumina ceramic good for heaters?

Alumina ceramic is very hard. It resists wear and chemicals. It spreads heat evenly. It withstands sudden temperature changes. This ensures reliable, long-lasting performance.

Is this heater plate safe for direct contact?

Yes, the surface stays safe to touch during operation. The ceramic insulates electricity well. It prevents electric shocks. Built-in safety features avoid overheating. Always follow installation guidelines.

Can you customize the heating plate for my machine?

Yes. We offer OEM and ODM services. We adjust the size, shape, power, and voltage. We fit your exact equipment needs. Provide your specifications. We make it work.

How do I maintain this heating plate?

Keep the surface clean. Remove dust or debris gently. Avoid sudden impacts or drops. Check electrical connections stay secure. Regular visual inspection helps spot early issues. Contact us for major servicing.

(OEM ODM Thermal Heater Disc High Temp Alumina Ceramic Heating Plate)

REQUEST A QUOTE

RELATED PRODUCTS

Porous Round and Square Alumina Honeycomb Ceramic Plate square Ceraimc Filter Plate

99% Al2o3 Industrial Fine Honeycomb Ceramic Plate Alumina Ceramic Disc

Ceramic Custom Product Plate With 99% Alumina Ceramic Plate Right Angle Multi-groove

Wear Resistant Alumina Ceramic Hex Tiles / Hexagonal Alumina Ceramic Lining Plate

130*30*40mm Customizable High Temperature 85% Alumina Ceramic Plate Industrial Use with 12mm Hole