Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

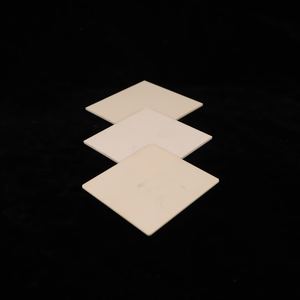

Overview of Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace

Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace)

Specification of Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace

These square ceramic plates are made from light weight aluminum oxide. We call this material alumina or Al2O3. They are developed for demanding furnace use. Home plates supply outstanding resistance to very high temperatures. They manage warmth more than 1500 levels Celsius. This makes them appropriate for lots of commercial heating processes.

Criterion plate sizes are readily available. Typical selections consist of 100mm x 100mm, 150mm x 150mm, 200mm x 200mm. Thickness usually ranges from 3mm as much as 20mm. We can produce custom dimensions as well. Simply inquire about your details requirements. The plates are cut specifically. They preserve limited dimensional resistances. This guarantees a good fit inside your furnace.

The product composition is 95% to 99.5% Al2O3. Higher purity generally means much better performance. It enhances resistance to extreme warmth and chemical strike. Home plates are extremely hard. They resist wear and abrasion effectively. This hardness likewise makes them good electric insulators. Their dielectric strength is high.

Thermal shock resistance is a vital attribute. Home plates can sustain fast home heating and cooling cycles. They stand up to splitting under unexpected temperature changes. This durability is important for heater applications. Home plates preserve their shape and stamina. They do not flaw easily under tons. Their mechanical toughness continues to be excellent even at heats.

Surface finish is commonly smooth. This aids prevent contamination of your work surfaces. It additionally makes cleaning less complicated between batches. These alumina plates are chemically inert. They withstand strike from numerous acids and antacids. This security protects your materials during processing. Common uses consist of furnace linings, kiln furnishings, setters, and diffusion watercraft elements.

(Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace)

Applications of Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace

Square alumina plates are crucial for heater job. They take care of extreme warmth well. They do not thaw or warp quickly. This makes them excellent inside warm areas. You locate them in kilns, heat therapy stoves, and industrial furnaces. They sustain components throughout firing. They serve as racks or setters. The plates safeguard the heater flooring. They protect costly heating elements also. Heavy items won’t harm the base. Hot products sit securely on them.

Home plates are very solid. They stand up to chemical corrosion. This includes extreme furnace ambiences. Molten steel sprinkles will not stick. Changes and slags cause little harm. This keeps heating system surfaces tidy. It prolongs the furnace life. Maintenance comes to be simpler. Downtime minimizes.

Another vital task is insulation. Alumina is a poor heat conductor. Plates positioned between warm areas and external walls block heat circulation. This saves energy. External heater areas stay cooler. Workers are more secure. Temperature level control enhances inside the furnace chamber. Heat remains where you require it.

These plates use thermal shock resistance. They deal with unexpected temperature level modifications well. Quick home heating or cooling cycles create much less anxiety. They fracture less commonly than various other materials. This reliability matters for duplicated furnace usage. They function as sturdy obstacles. They create safety linings. They produce secure platforms. Different heating system kinds require them. High pureness alumina ensures regular efficiency. It holds up against temperatures over 1600 ° C. This stability is important for top quality results. Furnace procedures depend on these resilient plates.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace

What temperature can these alumina plates handle?

They handle very high temperatures. Maximum continuous use is 1600°C (2912°F). Short peaks can hit 1750°C (3182°F). This makes them perfect for furnace work.

Will they crack under rapid heating or cooling?

They resist thermal shock very well. Square Al2o3 plates have low thermal expansion. Sudden temperature shifts are less likely to cause cracks. They are tougher than many ceramics.

How long do these plates last in a furnace?

They last a long time. Alumina ceramic resists wear, chemicals, and heat extremely well. They don’t degrade easily. You won’t need to replace them often. Expect reliable service life.

How do I clean residue off the plates?

Cleaning is straightforward. Let the plate cool completely first. Use a stiff brush or non-metallic scraper. For stubborn buildup, mild acids or sandblasting work. Avoid impacts though. Handle carefully.

Can I get custom sizes or shapes?

Yes, custom orders are possible. Standard sizes are readily available. Special shapes or thicknesses can be made. Contact us with your specific needs. We can discuss feasibility and cost.

(Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminium Oxide Circular White Round Block Alumina Ceramic Plate

Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board

Tactical vest panel 3a III IV 3456 Ceramic Plate Alumina Silicon Carbide PE Plate Vehicle Body Protective Vest Plate Carrier

High Purity Aluminum Oxide Al2o3 Alumina Ceramic Substrates/plate/sheet

High Temperature Resistance Alumina Ceramic Plate for Industrial Use Custom Cutting Processing Available