Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

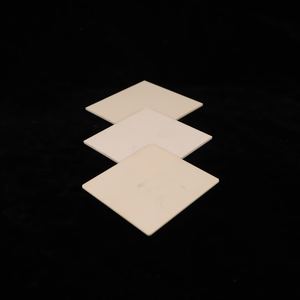

Overview of Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing

Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing)

Specification of Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing

These ceramic plates are made for tough textile manufacturing jobs. They are high-temperature industrial alumina ceramics. They are very strong and handle heat well. The main material is alumina oxide. The alumina content is over 92%. This makes them hard and resistant to wear. They last much longer than metal parts. They keep their shape even under heavy loads. The density is high. It is over 3.6 grams per cubic centimeter. This density helps them withstand impacts. They do not break easily. The surface is very smooth. This smoothness lets things slide easily. Friction is low. This protects fabrics from damage. Machines run smoother.

Heat resistance is a key feature. These plates work fine at temperatures up to 1600 degrees Celsius. They handle sudden temperature changes well. They do not crack like other materials might. Chemical resistance is another strength. They resist acids and alkalis. This is important for textile chemicals. They do not rust. They stay strong in humid conditions. Textile factories often have damp air. These ceramics are not affected.

The plates come in standard thicknesses. Common sizes are 5mm, 10mm, and 20mm thick. Width and length can be custom. We cut them to your machine’s exact needs. Common shapes are squares and rectangles. Round discs are also available. We machine them precisely. The edges are smooth and safe. They fit perfectly into looms, dryers, and finishers. They replace worn metal guides and supports. Performance improves. Fabric quality gets better. Downtime decreases.

We make these plates carefully. Quality control is strict. Each piece meets high standards. They are ready for heavy-duty industrial use. You can order small batches or large quantities. We deliver quickly.

(Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing)

Applications of Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing

Alumina ceramic plates are essential in textile manufacturing. These plates are made from high-purity alumina. They are incredibly strong. They resist high temperatures very well. This makes them perfect for tough factory conditions. Textile machines face constant friction and heat. Alumina ceramics handle this easily. They last much longer than metal parts. This saves money over time. Less replacement means less machine downtime. Production keeps running smoothly.

One key use is in thread guides. Thread moves quickly through these guides. Metal guides wear down fast. Alumina ceramic guides are much harder. They resist abrasion from the thread. Thread quality stays high. There are fewer breaks. Machines operate more efficiently. Ceramic cutting tools are also important. They stay sharp for longer periods. They make clean cuts consistently. Textile products have better edges. This improves the final product look.

Bearings in textile machines benefit too. Alumina ceramic bearings run cooler. They need less lubrication. This reduces maintenance work. Rollers can also be lined or coated with alumina ceramic. This protects the roller surface. It prevents damage from abrasive materials. Rollers stay functional longer. Heat shields made from alumina ceramic protect sensitive parts. They block high temperatures effectively. Nearby components stay safe. Electronic controls are protected this way.

Chemical resistance is another advantage. Textile processing uses various chemicals. Alumina ceramics do not corrode. They maintain their strength. They do not react with dyes or finishing agents. This ensures consistent performance. The surface stays smooth. There is no contamination risk. Textile manufacturers get reliable components. They improve machine life. They enhance product quality. They reduce operating costs significantly. These ceramics are a smart investment for modern textile plants.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing

What are these ceramic plates? These plates are made from special ceramic material. They handle extreme heat very well. Textile factories use them in machines. These machines need parts that can take high temperatures.

Why choose ceramic over metal? Metal parts wear out faster under heat. Ceramic plates last much longer. They save money by reducing replacements. They also keep machines running smoothly without stopping for fixes.

How hot can these plates get? These plates work fine up to 1600 degrees Celsius. This is much hotter than most factory processes require. Textile drying and heat treatment use high temperatures. These plates can handle that easily.

Do they resist wear? Yes, these plates are extremely hard. They resist scratches and surface damage much better than steel. This toughness means they keep their shape. Machines work precisely for longer periods.

Can we get custom sizes? Yes, factories often need specific shapes or sizes. We can make plates to fit your exact machine requirements. Tell us the dimensions you need. We will produce plates that fit perfectly.

(Whole High-Temperature Industrial Ceramic Alumina Ceramics High Quality Ceramic Plates for Textile Manufacturing)

REQUEST A QUOTE

RELATED PRODUCTS

Nanxiang Alumina Porcelain Honeycomb Ceramic Burn Plaque, BBQ Honeycomb Ceramic Plate

315t Alumina Ceramic Textile Tile Plate for Armored Body Armor Vest Hydraulic Press With Mould Pe Body armour Plate Machinr

Custom Ceramic Plate Slice 96% Alumina Thin Slice Sensor core

High Hardness Al2O3 99% Alumina Ceramic Body Protective Plate Ballistic Ceramic Armor Sheet

4mm 99% Pure Alumina Ceramic Plates With Square Hexagon