Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

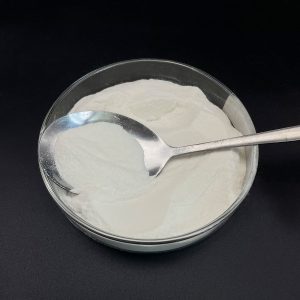

Overview of Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory

Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory (α-Al₂O₃) is an advanced ceramic material with ultrafine particle sizes (20-200nm) and high purity (99.9%+). Its exceptional surface area, hardness, and thermal stability make it ideal for high-performance applications, including ceramics, coatings, catalysts, and composite materials.

Key Features of Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory

Ultrafine Particle Size – 20-200nm for superior reactivity and dispersion.

High Purity (99.9%+) – Minimizes impurities for precision applications.

Excellent Thermal Stability – Withstands extreme temperatures (up to 1600°C).

Enhanced Mechanical Properties – Improves hardness, wear & corrosion resistance.

Wide Applications – Used in coatings, catalysts, electronics, and advanced ceramics.

(Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory)

Specification of Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory

Alumina powders are crucial for tough industrial jobs. They handle extreme warm and severe problems well. 2 major types are Nano Alpha High Purity Alumina Powder and White Fused Alumina Powder. Both job fantastic for refractory uses. Refractory methods products that stand up to warm like heating system cellular linings or kiln bricks.

Nano Alpha High Purity Alumina Powder is extremely fine and pure. It has little particles frequently under 100 nanometers. Its purity hits 99.99% or greater. This powder makes points solid and dense when heated. It bonds snugly with other products. So it enhances the efficiency of refractory items. It stops splits and wear in high-stress places.

White Fused Alumina Powder originates from thawing pure alumina. It gets squashed right into grains after cooling. This powder is white and really hard. It stands up to chemicals and warm up to 1800 ° C. The grains are sharp and lock with each other strongly. That makes frameworks secure under warmth. It’s more affordable than nano powder but still hard.

Refractory manufacturers utilize both powders for various demands. Nano powder fits high-end components requiring smooth finishes and stamina. Believe accuracy components or thin finishes. White fused alumina suits bulk things like fire blocks or castables. Building contractors mix it into concrete for kilns or heaters. It takes on thaw steel and slag.

These powders update warm barriers. They last longer and save repair costs. Factories select based upon their budget and heat degrees. Nano powder provides leading efficiency for crucial jobs. White integrated offers trustworthy outcomes for day-to-day high warmth.

(Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory)

Applications of Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory

Nano Alpha Alumina Powder uses exceptionally tiny bits. This makes it ideal for advanced ceramics. These porcelains need high density and strength. Small particles mean much better sintering at lower temperature levels. You obtain finer microstructures. This powder functions well in electronic devices. Think substrates and insulators. Its smooth surface finish matters there. It additionally matches high-performance cutting tools. They need hardness and use resistance.

High Pureness Alumina Powder hits 99.99% Al2O3 purity. Pollutants are really low. This is essential for demanding applications. Semiconductor production utilizes it. So does the optics market. It offers outstanding thermal security. It resists chemical assault also. Crucibles and tubes for high-temperature procedures typically utilize it. Its purity guarantees no contamination. This protects delicate materials or reactions.

White Fused Alumina Powder is made by thawing pure alumina. Then it’s cooled and crushed. This produces sharp, challenging grains. It has high solidity. It shows wonderful thermal shock resistance. This powder is key for refractory items. Believe heater cellular linings and kiln furniture. These face extreme warm and wear. It’s additionally essential for abrasives. Grinding wheels and sandpaper count on it. Its toughness under warmth is unmatched. Shops use it in molds and cores. It stands up to liquified steel contact. The powder bonds well with refractory binders. This constructs solid, resilient frameworks.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory

Alumina Powder FAQs

What is alumina powder?

Alumina powder is a fine material made from aluminum oxide. It’s very hard. It handles extreme heat well. This makes it ideal for tough industrial jobs. Refractories are a primary use.

What are the main types?

Three key types exist. Nano Alpha Alumina Powder has very tiny particles. This gives unique properties. High Purity Alumina Powder contains almost no impurities. White Fused Alumina Powder is made by melting high purity material. It forms strong crystals.

How hot can it withstand?

These powders resist very high temperatures. White Fused Alumina handles over 1800°C easily. Nano Alpha and High Purity types also perform exceptionally well under intense heat. This stability is vital for refractory linings.

Why is purity important?

High purity matters greatly. Impurities weaken the material. They lower its melting point. They cause poor performance in harsh conditions. High purity alumina keeps its strength. It lasts longer at high heat.

Is it safe to handle?

Handle all fine powders carefully. Alumina powder is generally chemically stable. Avoid breathing the dust. Use proper dust masks. Wear gloves. Good ventilation is essential. Store it dry away from moisture.

(Alumina Powder Nano Alpha High Purity Alumina Powder White Fused Alumina Powder For Refractory)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity 99.99% Nano Al2O3 Powder 30nm Alumina Powder Quote Nanoparticles Aluminum Oxide

Aluminium Oxide Al2o3 Powder Nano Alumina Nanopowder for Ceramic for Catalyst Aluminum Oxide Fine Powder

High Purity Industrial Grade Alumina Powder for Ceramic

High Purity 99.99% Nano Al2O3 Powder 100nm Alumina Powder Quote Nanoparticles Aluminum Oxide

Nano-alumina Powder Al2O3 for Coatings Cas 1344-28-1