Professional Premium Aluminum Oxide Products Supplier

1. Introduction

Just 24 hours ago, the International Culinary Research Symposium in Copenhagen unveiled a groundbreaking study on low-emission food browning techniques using high-purity alumina ceramic baking dishes. Led by Dr. Lena Voss at the Nordic Institute of Food Innovation, the team demonstrated how alumina’s near-zero thermal expansion and resistance to thermal shock allow for repeatable, contamination-free reactions at temperatures exceeding 1,600°C—conditions far beyond what conventional stoneware or metal bakeware can withstand. This marks a pivotal shift: alumina ceramic baking dish technology, once confined to industrial furnaces and aerospace labs, is now quietly transforming elite culinary science.

2. Why Alumina Ceramic? The Science Behind the Dish

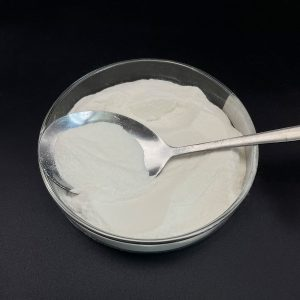

Alumina (Al₂O₃) is a technical ceramic prized for its hardness, electrical insulation, and exceptional stability under extreme heat. Unlike traditional porcelain or earthenware, high-purity alumina ceramic dishes—whether labeled as alumina baking ceramic dish, alumina ceramic casserole, or alumina ceramic ramekins—contain 95–99.8% aluminum oxide. This composition eliminates organic binders and impurities that could leach into food or degrade during rapid heating cycles. For culinary researchers, this means absolute control over Maillard reactions, sugar pyrolysis, or fat oxidation without interference from the vessel itself.

3. Niche Application: High-Temperature Food Chemistry Labs

In cutting-edge food labs, alumina ceramic dishes serve as reaction vessels for experiments that mimic industrial food processing at micro-scale. For instance, an alumina ceramic melting dish might be used to study the crystallization behavior of alternative sweeteners under controlled ramping profiles. Similarly, an alumina ceramic casserole with lid provides a sealed, inert environment for slow dehydration studies of plant-based proteins—critical for developing next-gen meat analogs. These applications demand materials that won’t crack, warp, or outgas, making alumina ceramic dinner plates and alumina ceramic serving bowls ideal even when repurposed from tableware lines.

- Alumina ceramic plates for painting are sometimes adapted as sample trays for spectral analysis due to their smooth, non-reflective white surface.

- Alumina black ceramic plates offer contrast for high-resolution imaging of char formation during combustion experiments.

- Alumina ceramic butter dish with lid models are used to test lipid oxidation rates in oxygen-controlled chambers.

4. Beyond the Oven: Cross-Industry Synergies

Interestingly, many of the same properties that make alumina ceramic oven dishes suitable for labs also appear in industrial components. For example, alumina ceramic tubes used in thermocouple protection share manufacturing processes with thick-walled alumina casserole ceramic dishes. Similarly, alumina grinding discs designed for pottery finishing are made from the same sintered powders as high-end alumina white ceramic plates. This cross-pollination allows culinary labs to source custom shapes—like alumina ceramic disc taps or alumina ceramic capillary tubes—for micro-dosing or vapor capture during flavor compound isolation.

5. Practical Considerations for Adoption

While alumina ceramic dishes for oven use are commercially available from specialty suppliers, researchers often collaborate with alumina ceramic crucible manufacturers to produce bespoke geometries. Cost remains a barrier—alumina ceramic plates black or alumina handcrafted ceramic plates can cost 5–10x more than standard stoneware—but the payoff in data integrity and experimental repeatability justifies the investment. Moreover, durability offsets long-term expenses: an alumina ceramic serving platter can endure thousands of thermal cycles without glaze degradation or microfractures.

6. Future Outlook

As sustainable food tech accelerates, expect alumina ceramic applications to expand. Startups are already testing alumina ceramic Christmas plates ceramic not just for festive tableware, but as standardized substrates for edible ink printing and biodegradable coating trials. Meanwhile, alumina ceramic childrens plates are being evaluated for microwave sterilization resilience in institutional kitchens. The line between labware and tableware continues to blur, driven by alumina’s unmatched performance.

7. Conclusion

The alumina ceramic baking dish is far more than a kitchen novelty—it’s a precision tool enabling the future of food science. From alumina salad ceramic bowl prototypes testing enzymatic browning to alumina ceramic sugar dish units monitoring sucrose decomposition, these ceramics offer purity, stability, and versatility unmatched by alternatives. As culinary innovation pushes into higher temperatures and cleaner chemistries, alumina will remain at the heart of the revolution—both in the lab and, increasingly, on the plate.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.