Professional Premium Aluminum Oxide Products Supplier

1. Introduction

If you’ve ever wondered why some ceramic bakeware lasts longer, heats more evenly, or looks stunning straight from oven to table, the secret might lie in its material—specifically, alumina ceramic. Unlike standard stoneware or porcelain, alumina ceramic baking dishes leverage the exceptional properties of aluminum oxide (Al₂O₃) to deliver superior performance in high-heat environments.

From everyday meals to festive gatherings, items like the alumina ceramic casserole dish, alumina butter ceramic dish, or even alumina ceramic Christmas plates are gaining popularity for their blend of function and elegance. But what makes alumina stand out? Let’s dive in.

2. What Makes Alumina Ceramic Unique?

Alumina ceramic is made from refined aluminum oxide powder fired at extremely high temperatures—often above 1,600°C. This process creates a dense, non-porous structure that’s harder than most ceramics and highly resistant to thermal shock.

Compared to traditional earthenware or even some porcelain, alumina ceramic dishes for oven use maintain structural integrity under rapid temperature changes. That means your alumina oven ceramic dish won’t crack when moved from freezer to oven—a common issue with lesser ceramics.

- Exceptional heat retention and even distribution

- Non-reactive surface safe for acidic foods

- Scratch-resistant and durable for daily use

3. Comparing Alumina Baking Dishes to Other Ceramic Types

Not all ceramic bakeware is created equal. Standard ceramic dishes often contain lower percentages of alumina or rely on clay bodies that aren’t optimized for thermal performance. In contrast, true alumina ceramic baking dishes typically contain 70–99% alumina, significantly boosting strength and thermal stability.

For example, an alumina casserole ceramic dish with lid will outperform a generic ceramic casserole in repeated high-heat cycles. Similarly, alumina ramekin ceramic cups handle broiler temperatures better than conventional ramekins.

Even brands like Staub—known for enameled cast iron—have explored alumina-enhanced lines. While ‘alumina baking dish Staub’ isn’t a standard product name, the integration of high-alumina ceramics in premium cookware reflects growing industry recognition of its benefits.

4. Everyday and Specialty Uses

Alumina ceramic isn’t just for baking casseroles. Its versatility spans the entire dining experience:

- Alumina ceramic dinner plates and alumina dinner ceramic plates offer chip resistance and a smooth, hygienic surface.

- Alumina black ceramic plates and alumina ceramic plates black provide a modern, dramatic look without compromising safety.

- Alumina ceramic childrens plates benefit from the material’s durability and non-toxic finish.

Holiday entertaining shines with themed pieces like alumina Christmas ceramic platter or alumina ceramic Christmas plates, which combine festive design with oven-to-table convenience.

Even niche items like alumina ceramic sugar dish or alumina ceramic butter dish with lid maintain freshness while adding elegance to the table.

5. Aesthetic Variety Without Sacrificing Function

One misconception is that high-performance ceramics lack visual appeal. Not so with alumina. Manufacturers produce everything from minimalist alumina white ceramic plates to intricate alumina blue white porcelain plates inspired by classic Chinese designs.

Handcrafted options like alumina handcrafted ceramic plates merge artisanal beauty with industrial-grade durability. And for creative types, alumina ceramic plates for painting offer a stable, heat-resistant canvas for custom tableware.

Serving is equally elevated: alumina ceramic serving bowls, alumina ceramic serving platter, and alumina salad ceramic bowl all transition seamlessly from kitchen prep to formal presentation.

6. Clarifying Common Confusions

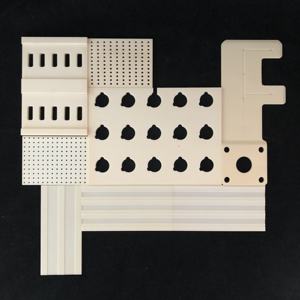

It’s important to distinguish true alumina ceramic kitchenware from industrial alumina components like alumina discs, alumina ceramic tubes, or alumina crucibles—used in labs, furnaces, or plumbing. While they share the same base material, kitchen-grade alumina ceramic is formulated for food safety and aesthetics, not extreme industrial conditions.

Terms like ‘alumina ceramic disc taps’ or ‘alumina thermocouple protection tubes’ refer to technical applications and shouldn’t be confused with bakeware. Your alumina ceramic dish is designed for lasagna, not laser tubes or furnace linings.

7. Care and Longevity Tips

To maximize the life of your alumina ceramic dishes for oven use:

- Avoid sudden temperature shocks (though they’re more resistant than most).

- Use non-abrasive cleaners to preserve glaze integrity.

- Store carefully to prevent chipping, even though alumina is harder than standard ceramic.

With proper care, an alumina ceramic casserole with lid or set of alumina ceramic plates and bowls can last decades—making it a sustainable investment.

8. Conclusion

Alumina ceramic baking dishes represent the sweet spot between science and style. Whether you’re using an alumina oven dish ceramic for roasting vegetables, serving guests on alumina ceramic black plates, or storing butter in an alumina butter dish ceramic with lid, you’re benefiting from advanced material engineering disguised as everyday tableware.

As consumers seek durable, non-toxic, and beautiful kitchen solutions, alumina-based ceramics are poised to move from niche favorite to mainstream essential.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.