Professional Premium Aluminum Oxide Products Supplier

1. Introduction

Alumina ceramic baking dish products are widely recognized for their durability and aesthetic appeal in domestic kitchens. However, beyond culinary use lies a sophisticated application domain where these components serve critical roles in scientific and industrial processes. In high-temperature laboratories, the same material composition that ensures even baking in an oven also enables precise thermal management during material synthesis, ash testing, and sample preparation. This article examines the specialized deployment of alumina ceramic baking dishes—and related forms such as alumina ceramic casserole dishes, alumina ceramic ramekins, and alumina ceramic crucibles—in advanced technical environments.

2. Material Properties Enabling Laboratory Use

2.1. Thermal and Chemical Resilience

Alumina (Al₂O₃), particularly in its high-purity (>95%) form, exhibits a melting point exceeding 2,000°C and maintains structural integrity up to 1,700°C in oxidizing atmospheres. This makes alumina ceramic dishes ideal for applications requiring repeated exposure to extreme heat without deformation or contamination. Unlike standard stoneware or porcelain, alumina ceramic plates for dinner or alumina white ceramic plates used in labs resist thermal shock, ensuring reliability during rapid heating or cooling cycles.

2.2. Inertness and Purity

High-purity alumina is chemically inert to most acids, alkalis, and molten metals below its degradation threshold. This property is crucial when handling reactive samples in analytical chemistry or metallurgy. For instance, an alumina ceramic butter dish with lid may be repurposed in trace-metal analysis to store ultra-pure reagents, while an alumina ceramic casserole with lid can safely contain fluxes during X-ray fluorescence (XRF) sample fusion.

3. Niche Laboratory Applications

3.1. High-Temperature Sample Preparation

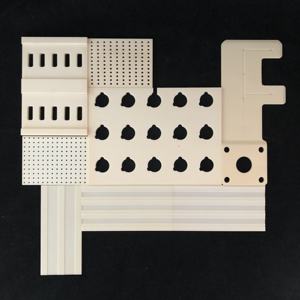

In materials science labs, alumina ceramic baking dishes function as open crucibles for ash content determination, calcination of powders, and sintering precursors. Their flat geometry—similar to an alumina oven ceramic dish—allows uniform heat distribution across samples, unlike deeper crucibles that may create thermal gradients. Researchers often select alumina ceramic dishes for oven use due to their nonporous surface, which prevents sample absorption and cross-contamination.

3.2. Semiconductor and Thin-Film Processing

During wafer cleaning or annealing steps, alumina ceramic serving platters or alumina ceramic serving bowls are employed as temporary carriers for silicon wafers. Their electrical insulation and particle-free surfaces minimize defect formation. Moreover, alumina ceramic plates for painting—originally designed for artistic glazing—are adapted as substrates for depositing thin-film coatings under controlled atmospheres.

3.3. Analytical Chemistry and Spectroscopy

In inductively coupled plasma (ICP) and atomic absorption spectroscopy (AAS), sample digestion often requires evaporation to dryness. Alumina ceramic ramekins or small alumina ceramic bowl plates provide contamination-free vessels that withstand aggressive acids like hydrofluoric acid (when properly passivated). Similarly, alumina ceramic sugar dishes or alumina salad ceramic bowls are repurposed for drying hygroscopic standards due to their low moisture retention.

4. Comparison with Related Alumina Components

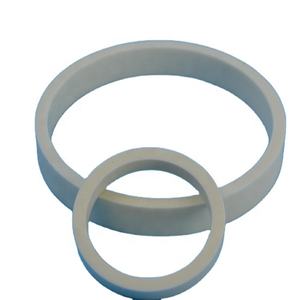

While alumina ceramic baking dishes excel in open-vessel applications, other engineered alumina forms address complementary needs. Alumina thermocouple protection tubes shield sensors in furnaces, and alumina ceramic tubes for high temperature serve as reaction chambers. Meanwhile, alumina ceramic crucibles—often cylindrical with lids—are preferred for melting metals like gold or aluminum alloys. The choice between an alumina casserole ceramic dish and a dedicated crucible depends on required volume, geometry, and lid compatibility.

5. Practical Considerations for Lab Adoption

- Ensure the alumina content is ≥95% for high-temperature stability; lower grades may contain silica or fluxes that leach at elevated temperatures.

- Avoid thermal shock by preheating dishes gradually in muffle furnaces.

- Clean using ultrasonic baths with dilute nitric acid, not abrasive tools that could compromise surface integrity.

- Verify compatibility with specific reagents; while inert to most chemicals, molten alkalis and phosphates can attack alumina above 1,000°C.

6. Conclusion

The transition of alumina ceramic baking dish variants from kitchen shelves to laboratory benches underscores their versatility as engineered ceramics. Whether used as an alumina oven dish ceramic for ash testing, an alumina ceramic serving platter for wafer handling, or even an alumina ceramic Christmas plate repurposed for calibration standards, their performance stems from intrinsic material excellence. As research demands ever-greater purity and thermal control, these unassuming vessels continue to prove indispensable in niche scientific applications far beyond their original design intent.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.