Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a recent development reported just hours ago by Kitchen & Bath Design News (May 22, 2024), premium cookware brands are increasingly turning to high-alumina ceramics for bakeware due to rising consumer demand for non-toxic, thermally stable, and aesthetically refined kitchen tools. This shift underscores a broader trend toward engineered ceramics that combine functionality with elegance—making the alumina ceramic baking dish more than just a kitchen staple, but a statement piece.

Unlike traditional stoneware or porcelain, alumina-based ceramics contain a high percentage of aluminum oxide (Al₂O₃), often exceeding 90%. This composition grants exceptional heat resistance, mechanical strength, and chemical inertness—qualities that translate directly into superior performance in the oven and on the dining table.

2. What Makes Alumina Ceramic Unique?

Alumina ceramic is not your average pottery clay. It’s an advanced technical ceramic prized in aerospace, electronics, and now, culinary arts. The key differentiator lies in its purity and sintering process. While standard ceramic dishes may crack under rapid temperature shifts, an alumina ceramic oven dish maintains structural integrity from freezer to broiler.

This resilience stems from alumina’s low thermal expansion coefficient and high melting point (over 2,000°C). As a result, items like the alumina ceramic casserole with lid or alumina oven ceramic dish can handle repeated thermal cycling without warping or glaze degradation.

3. Comparing Alumina Ceramic Bakeware Types

Not all alumina ceramic dishes are created equal. Manufacturers vary in alumina content, firing temperature, and finishing techniques—leading to distinct categories suited for different uses:

- Everyday Dinnerware: Alumina white ceramic plates and alumina black ceramic plates offer chip resistance and a smooth, non-porous surface ideal for daily meals. Their dense structure prevents staining from tomato sauces or turmeric.

- Specialized Serving Pieces: The alumina ceramic serving platter and alumina ceramic serving bowls maintain food temperature longer due to low thermal conductivity—perfect for buffets or holiday gatherings like Christmas, where alumina christmas ceramic platter sets are gaining popularity.

- Functional Accessories: Small-format items like the alumina ceramic butter dish with lid, alumina ceramic sugar dish, and alumina ceramic ramekins benefit from alumina’s moisture resistance, keeping contents fresh without metallic aftertastes.

4. Oven Performance vs. Traditional Ceramics

When pitted against standard earthenware or even stoneware, alumina ceramic dishes for oven use outperform in three critical areas: thermal shock resistance, longevity, and safety. Unlike some glazed ceramics that may leach lead or cadmium at high temperatures, high-purity alumina is inherently non-toxic and FDA-compliant.

Brands like Staub have begun incorporating alumina-enhanced formulas into lines such as the alumina baking dish staub, blending French craftsmanship with advanced material science. These pieces distribute heat evenly—ideal for delicate custards in alumina ramekin ceramic or slow-roasted vegetables in an alumina casserole ceramic dish.

5. Beyond Baking: Unexpected Uses of Alumina Ceramics

While the focus here is culinary, it’s worth noting that the same material used in your alumina ceramic dinner plates also appears in industrial contexts—like alumina ceramic tubes for furnaces or alumina crucibles for metal melting. However, kitchen-grade alumina is formulated for food contact, with smoother finishes and decorative options like alumina blue white porcelain plates or hand-painted alumina ceramic plates for painting.

Even children’s tableware benefits: alumina ceramic childrens plates are lighter than stoneware yet tougher than melamine, offering a safe, break-resistant alternative without plastic concerns.

6. Care and Longevity Tips

To maximize the life of your alumina ceramic plate bowls or alumina ceramic bowl plates, avoid sudden temperature shocks (e.g., placing a hot dish directly on a cold countertop). Though highly durable, they’re still ceramic—so gentle handling matters.

Cleaning is straightforward: the non-porous surface resists grease and odors, making dishwasher use safe. For stubborn stains, baking soda paste works without scratching the glaze.

7. Conclusion

The alumina ceramic baking dish represents the convergence of engineering precision and culinary artistry. Whether you’re using an alumina ceramic casserole, serving salad in an alumina salad ceramic bowl, or displaying cookies on an alumina ceramic christmas plates set, you’re leveraging a material trusted far beyond the kitchen. As consumer awareness grows, expect to see more innovation in this space—proving that sometimes, the best bakeware isn’t just made for the oven, but engineered for excellence.

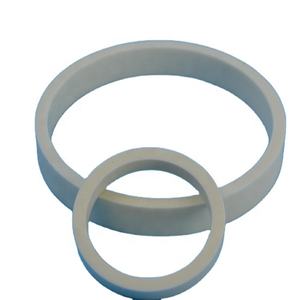

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.