Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a recent development reported by The Spoon on May 26, 2024, leading kitchenware brands are increasingly adopting high-purity alumina ceramics for premium bakeware due to rising consumer demand for non-toxic, durable, and thermally stable cookware. This shift underscores a broader trend toward engineered ceramics in everyday kitchen use—moving beyond industrial applications into homes seeking safety, performance, and elegance.

Alumina ceramic baking dishes—crafted from aluminum oxide (Al₂O₃)—combine exceptional heat resistance, chemical inertness, and aesthetic versatility. Unlike conventional ceramic or glass bakeware, alumina-based products maintain structural integrity at extreme temperatures, making them ideal for everything from slow roasting to broiling. This article explores the features, uses, and benefits of alumina ceramic baking dishes and related tableware.

2. What Is an Alumina Ceramic Baking Dish?

An alumina ceramic baking dish is a high-performance kitchen vessel made primarily from alumina (aluminum oxide), a refined ceramic material known for its hardness, thermal stability, and non-reactivity. These dishes are engineered to withstand temperatures exceeding 1,600°C (2,912°F) in industrial settings, though kitchen-grade versions are optimized for domestic ovens (typically up to 500°F or 260°C).

Unlike standard stoneware or porcelain, alumina ceramic baking dishes offer superior thermal shock resistance, meaning they can transition safely from freezer to oven without cracking. This makes them perfect for meal prep, storage, and reheating—all in the same dish.

3. Key Benefits of Alumina Ceramic Bakeware

- Non-porous surface prevents odor and stain absorption, ensuring food purity and easy cleaning.

- Chemically inert—won’t leach metals or toxins into food, even with acidic ingredients like tomatoes or citrus.

- Retains heat evenly, promoting consistent cooking and browning.

- Scratch- and chip-resistant, offering long-term durability compared to glass or standard ceramic.

- Available in a range of finishes, including glossy white, matte black, and handcrafted artisanal designs.

4. Versatility Beyond Baking: Alumina Ceramic Tableware

The utility of alumina ceramics extends far beyond the oven. Consumers now use alumina ceramic dishes for a wide array of dining and serving needs:

- Alumina ceramic dinner plates and alumina dinner ceramic plates provide elegant, durable options for everyday or formal settings.

- Alumina white ceramic plates and alumina black ceramic plates (also marketed as alumina ceramic black plates or alumina ceramic plates black) cater to minimalist and modern tablescapes.

- Specialized items like alumina ceramic butter dish with lid, alumina ceramic sugar dish, and alumina ceramic ramekins offer functional storage with aesthetic cohesion.

- Seasonal collections, such as alumina ceramic christmas plates and alumina christmas ceramic platter, blend festive design with high-performance material.

Families also appreciate alumina ceramic childrens plates for their chip resistance and safety, while artists use alumina ceramic plates for painting due to their smooth, non-absorbent surfaces.

5. Oven-Safe and Multi-Functional Designs

Many alumina ceramic dishes are explicitly designed for oven use. Products labeled as alumina ceramic dishes for oven, alumina oven ceramic dish, or alumina oven dish ceramic undergo rigorous thermal testing to ensure safety under high heat.

Popular configurations include the alumina ceramic casserole with lid, alumina casserole ceramic dish, and alumina ceramic casserole—ideal for one-pot meals, gratins, and baked pastas. Similarly, alumina salad ceramic bowl and alumina ceramic serving bowls are suitable for both cold and hot preparations.

Notably, some premium lines—such as those inspired by European craftsmanship—may be referenced in searches as alumina baking dish staub, though Staub itself typically uses enameled cast iron; the term reflects consumer interest in high-end, durable bakeware alternatives.

6. Clarifying Misconceptions: Alumina vs. Industrial Ceramics

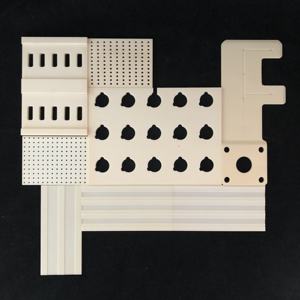

While the keyword list includes industrial components like alumina ceramic tubes, alumina crucibles, and alumina grinding discs, it’s important to distinguish kitchen-grade alumina ceramics from their technical counterparts.

Kitchenware uses food-safe, high-purity alumina formulated for culinary use—not the same as alumina ceramic piping, alumina thermocouple protection tubes, or alumina silicon carbide bricks used in furnaces or laboratories. Similarly, alumina discs for taps or alumina ceramic disc magnets serve entirely different purposes and are not relevant to cookware.

Consumers should ensure products are labeled as food-grade and compliant with FDA or equivalent safety standards.

7. Care and Longevity

Alumina ceramic baking dishes and tableware are dishwasher-safe and resistant to microwave and freezer use. To preserve finish and longevity, avoid sudden temperature shocks (e.g., placing a hot dish directly on a cold countertop) and use non-abrasive cleaners.

Their durability means fewer replacements over time, making them a sustainable investment for eco-conscious households.

8. Conclusion

The alumina ceramic baking dish represents the convergence of advanced materials science and practical kitchen innovation. With unmatched thermal performance, safety, and design flexibility—from alumina ceramic serving platter to alumina handcrafted ceramic plates—these products meet the demands of modern cooking and dining. As consumer awareness grows, alumina-based ceramics are poised to become a staple in kitchens worldwide, offering a blend of function, safety, and timeless style.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Alumina. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.