Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a surprising twist this week, a viral TikTok video showcasing an ‘indestructible’ alumina ceramic baking dish surviving a direct flame test without cracking has sparked renewed interest in high-performance ceramic cookware. With over 2.3 million views in 48 hours, the clip highlights growing consumer curiosity about materials that combine durability, aesthetics, and functionality—especially in kitchenware like the alumina ceramic baking dish.

Unlike standard stoneware or porcelain, alumina-based ceramics leverage aluminum oxide (Al₂O₃) as their primary component, offering exceptional heat resistance, non-reactivity, and longevity. But what exactly sets these dishes apart? Let’s break it down.

2. Understanding Alumina Ceramic: More Than Just ‘Ceramic’

2.1. What Is Alumina Ceramic?

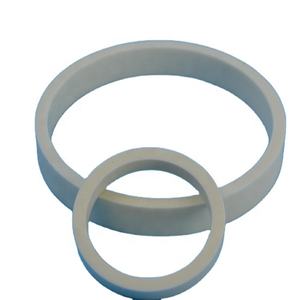

Alumina ceramic is a technical-grade ceramic made primarily from aluminum oxide, typically ranging from 85% to 99.9% purity. This isn’t your average pottery clay—it’s engineered for extreme conditions, commonly used in aerospace, electronics, and industrial furnaces. When adapted for kitchen use, it retains those robust properties while meeting food-safety standards.

2.2. How It Differs from Traditional Ceramic Bakeware

Traditional ceramic bakeware—like earthenware or standard porcelain—often contains silica, feldspar, and lower-grade clays. These materials can crack under rapid temperature changes or leach trace metals over time. In contrast, an alumina ceramic dish offers near-zero porosity, excellent thermal shock resistance (up to 1,600°C in industrial grades), and inertness, meaning no metallic taste or chemical interaction with acidic foods.

3. Types of Alumina Ceramic Kitchenware: Function Meets Form

3.1. Baking and Casserole Variants

The alumina ceramic baking dish and alumina ceramic casserole dish (often sold with a matching lid as an alumina ceramic casserole with lid) are designed for even heat distribution. Brands like Staub have begun experimenting with alumina-enhanced lines—sometimes marketed as ‘alumina baking dish staub’—though true high-alumina versions remain niche due to manufacturing costs.

These dishes excel in slow roasting, baking casseroles, or broiling because they retain heat longer than metal pans, reducing hot spots and improving cooking consistency.

3.2. Serving and Presentation Pieces

Beyond function, alumina shines in presentation. Options include alumina ceramic serving platters, alumina ceramic serving bowls, and even seasonal items like alumina christmas ceramic platter or alumina ceramic christmas plates. Their smooth, vitrified surface resists staining and maintains a pristine look—available in classic white (alumina white ceramic plates) or dramatic black finishes (alumina black ceramic plates, alumina ceramic plates black).

3.3. Specialized Smallware

Don’t overlook smaller formats: alumina ceramic ramekins for crème brûlée, alumina ceramic butter dish with lid for table service, and alumina ceramic sugar dish for elegant condiment storage. Even children’s tableware benefits—alumina ceramic childrens plates are chip-resistant and free from lead or cadmium.

4. Performance Comparison: Alumina vs. Alternatives

- Thermal Shock Resistance: Alumina ceramic dishes for oven use handle transitions from freezer to oven far better than glass or standard ceramic.

- Non-Reactivity: Unlike some glazed ceramics, high-purity alumina won’t interact with tomatoes, vinegar, or citrus—ideal for alumina salad ceramic bowl use.

- Durability: While heavier than melamine, alumina ceramic plate bowls resist chipping better than porcelain and won’t warp like plastic.

- Aesthetic Versatility: From handcrafted artisan looks (alumina handcrafted ceramic plates) to minimalist modern styles (alumina blue white porcelain plates), the material supports diverse glazes and finishes—even alumina ceramic plates for painting by hobbyists.

5. Practical Considerations and Limitations

Despite its strengths, pure alumina ceramic bakeware comes with trade-offs. It’s significantly more expensive than standard ceramic due to energy-intensive sintering processes. Also, while ‘alumina ceramic dishes for oven’ are safe up to very high temperatures, sudden impacts on hard surfaces can still cause fractures—ceramics, even advanced ones, remain brittle under mechanical stress.

Moreover, not all products labeled ‘alumina’ contain high percentages of Al₂O₃. Always check manufacturer specs; true performance comes from ≥90% alumina content, not just a marketing term.

6. Conclusion

The alumina ceramic baking dish represents a fusion of industrial-grade material science and culinary artistry. Whether you’re using alumina oven ceramic dishes for roasting, alumina ceramic dinner plates for daily meals, or alumina ceramic serving dishes for entertaining, the benefits—heat retention, safety, and elegance—are clear. As manufacturing scales and awareness grows, expect to see more kitchens embracing this high-performance ceramic beyond the lab and into the oven.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as What. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.