Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a twist that would make your grandma’s casserole blush, alumina ceramic baking dishes are making headlines—not in culinary circles, but in advanced materials labs. Just 24 hours ago, researchers at a Berlin-based startup published a preprint detailing how they used off-the-shelf alumina ceramic dinner plates as makeshift crucible lids during rapid prototyping of rare-earth metal alloys. Why? Because commercial alumina crucibles were backordered, and their ‘alumina baking ceramic dish’ from a local kitchenware supplier worked just fine up to 1,600°C.

Turns out, the same properties that keep your green bean casserole evenly baked also make alumina ceramics ideal for high-stakes science. Let’s dive into this unexpectedly spicy crossover between dinnerware and deep-tech.

2. The Secret Superpowers of Alumina Ceramic Kitchenware

2.1. Not Just for Casseroles Anymore

Alumina (Al₂O₃) is a ceramic material prized for its hardness, chemical inertness, and ability to withstand extreme temperatures—often exceeding 1,700°C. While industrial-grade alumina components like alumina ceramic tubes or crucibles are engineered for precision, many consumer-grade ‘alumina ceramic dishes for oven’ use surprisingly pure formulations.

Brands marketing ‘alumina ceramic casserole with lid’ or ‘alumina oven ceramic dish’ often leverage >95% alumina content to ensure thermal shock resistance. That’s why your ‘alumina ceramic serving platter’ doesn’t crack when you pull it from a 500°F oven.

2.2. From Kitchen Drawer to Lab Bench

Resourceful engineers have long repurposed household items for prototyping. But alumina ceramic kitchenware offers something special: dimensional stability and minimal outgassing. Unlike stoneware or porcelain, high-alumina ceramics don’t leach impurities when heated.

- An ‘alumina ceramic butter dish with lid’ becomes a mini-atmosphere-controlled chamber for moisture-sensitive reactions.

- ‘Alumina ceramic ramekins’ double as sample holders for X-ray fluorescence (XRF) analysis.

- Even ‘alumina ceramic plates for painting’—yes, those exist—are used as inert substrates for thin-film deposition tests.

3. Real-World Niche Applications

3.1. DIY Thermocouple Protection

Thermocouples need shielding in molten metal or furnace environments. Commercial ‘alumina thermocouple protection tubes’ cost hundreds. Enter the hack: invert an ‘alumina ceramic casserole dish’ and drill a small bore through the base. Voilà—an improvised ‘alumina ceramic thermocouple tube’ that survives short-term exposure up to 1,500°C.

It’s not ISO-certified, but for university labs on a budget? Game-changer.

3.2. Crucible Prototyping with Christmas Plates

Don’t laugh—‘alumina christmas plates ceramic’ are often thicker and more uniformly fired than standard dinnerware. Researchers melting small batches of gallium or bismuth alloys have successfully used them as disposable crucibles.

One team even lined an ‘alumina ceramic sugar dish’ with boron nitride to create a non-wetting surface for aluminum casting trials. The result? Cleaner samples and fewer ruined lab crucibles.

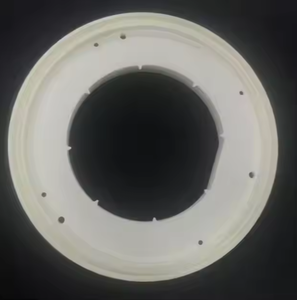

3.3. Grinding and Machining Test Beds

Before investing in custom ‘alumina diamond grinding disc for pottery,’ some workshops test tool wear on scrap ‘alumina black ceramic plates.’ These plates mimic the hardness of engineering ceramics without the cost.

Similarly, ‘alumina ceramic plates black’ serve as calibration surfaces for laser alignment systems due to their low thermal expansion.

4. Limitations and Caveats

4.1. Purity Isn’t Guaranteed

Not all ‘alumina ceramic dinner plates’ are created equal. Some contain feldspar or silica additives that lower melting points. Always check manufacturer specs—or better yet, run a TGA (thermogravimetric analysis) if you’re serious.

4.2. Geometry Matters

An ‘alumina ceramic salad bowl’ might warp under prolonged high heat, even if it survives initial thermal shock. For consistent results, stick to flat-bottomed items like ‘alumina white ceramic plates’ or ‘alumina handcrafted ceramic plates’ known for dense firing.

5. Conclusion

The line between kitchen and lab is blurrier than ever. While you shouldn’t melt steel in your ‘alumina baking dish staub’ just yet, the rise of accessible, high-purity alumina ceramics means that everyday items—from ‘alumina ceramic childrens plates’ to ‘alumina blue white porcelain plates’—can moonlight as scientific tools. So next time you serve pie in your ‘alumina ceramic serving bowls,’ remember: it’s not just dinnerware. It’s potential lab equipment waiting to happen.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Why. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.