Professional Premium Aluminum Oxide Products Supplier

1. Introduction

In a surprising development reported just yesterday by Materials Today, researchers at the Fraunhofer Institute have begun repurposing high-purity alumina ceramic kitchenware—including baking dishes and casserole dishes—for small-scale molten metal containment trials in resource-limited labs. This unconventional approach leverages the material’s innate resistance to thermal shock and chemical corrosion, typically associated with industrial-grade alumina components like crucibles and thermocouple protection tubes.

Though most consumers recognize an alumina ceramic baking dish as a durable, non-reactive vessel for roasting vegetables or baking casseroles, its composition—often 95–99.8% aluminum oxide (Al₂O₃)—grants it properties far beyond the kitchen. This article dives into the niche, high-stakes applications where everyday-looking alumina ceramic dishes find unexpected utility.

2. Why Alumina Ceramic? The Science Behind the Strength

Alumina ceramic is prized for its extreme hardness, high melting point (over 2,000°C), electrical insulation, and resistance to acids, alkalis, and oxidation. These traits make it ideal not just for dinnerware like alumina ceramic dinner plates or alumina white ceramic plates, but also for demanding technical environments.

Unlike standard stoneware or porcelain, high-alumina ceramics maintain structural integrity under rapid temperature changes—a property critical in both baking and industrial processing. This is why an alumina oven ceramic dish can go from freezer to broiler without cracking, and why an alumina ceramic crucible can safely melt gold or steel in a foundry.

3. From Kitchen to Lab: Repurposing Alumina Baking Ware

In academic and startup labs with limited budgets, commercially available alumina ceramic baking dishes—often marketed as alumina baking ceramic dish or alumina casserole ceramic dish—are being used as low-cost alternatives to custom crucibles for preliminary material synthesis. Their flat, wide geometry allows for even heating and easy observation of reactions.

- Researchers have used alumina ceramic casserole with lid units to hold precursor powders during solid-state reactions.

- Small-scale glass frit melting trials have employed alumina ceramic ramekins due to their precise volume control and thermal stability.

- Even alumina ceramic butter dish with lid containers have been sterilized and repurposed for storing ultra-pure chemical reagents where metal contamination must be avoided.

4. Industrial Cousins: Alumina Tubes, Discs, and Crucibles

While a domestic alumina ceramic baking dish may serve in a pinch, purpose-built industrial components offer optimized performance. Alumina ceramic tubes—such as alumina thermocouple protection tubes or alumina high temperature ceramic tubes—are engineered for furnace atmospheres, protecting sensitive sensors from corrosive gases and extreme heat.

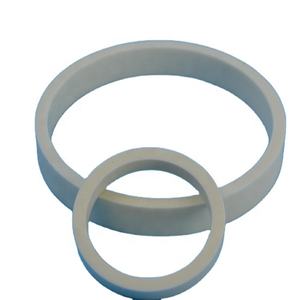

Similarly, alumina ceramic disc taps and alumina ceramic grinding discs are used in precision fluid control and surface finishing, respectively. These share the same base material as your alumina ceramic serving platter but are manufactured to tighter tolerances and higher purity standards.

Crucibles represent the most direct industrial counterpart. An alumina ceramic crucible for melting gold or steel must withstand not only heat but also reactive molten metals—something a standard alumina ceramic casserole dish isn’t rated for, though the material science is closely related.

5. Design Considerations for Dual-Use Applications

Not all alumina ceramic dishes are created equal. Those intended for industrial repurposing should be:

- Made from ≥95% pure alumina (check manufacturer specs)

- Free of glazes or decorative coatings that may outgas or contaminate processes

- Verified for thermal shock resistance (e.g., usable from -40°C to 1,000°C)

Interestingly, some artisanal brands now market ‘lab-to-table’ alumina handcrafted ceramic plates that meet both food safety and basic materials testing standards—bridging the gap between function and form.

Even seasonal items like alumina christmas plates ceramic or alumina ceramic christmas plates are being studied for their potential as substrates in low-temperature thin-film deposition due to their smooth, non-porous surfaces.

6. Safety and Limitations

While versatile, alumina ceramic dishes have limits. A standard alumina oven dish ceramic isn’t designed for direct flame contact or temperatures above 1,200°C—unlike specialized alumina ceramic tubes for furnace use, which can endure 1,700°C+.

Moreover, mechanical strength drops significantly above 1,000°C, so load-bearing applications (like stacking or supporting heavy samples) require engineering-grade components like alumina ceramic bricks or alumina ceramic bearing elements.

7. Conclusion

The humble alumina ceramic baking dish exemplifies how advanced ceramics quietly permeate both domestic and industrial spheres. From holding holiday cookies to containing experimental alloys, its underlying material—alumina—proves remarkably adaptable. As labs seek cost-effective, high-performance solutions, the boundary between kitchenware and scientific apparatus continues to blur, proving that sometimes, the best tool for a high-tech job might just come from your oven.

Our Website founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials such as Can. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.